A Rotary Table and Automation for a Measurement System

Rotary Table

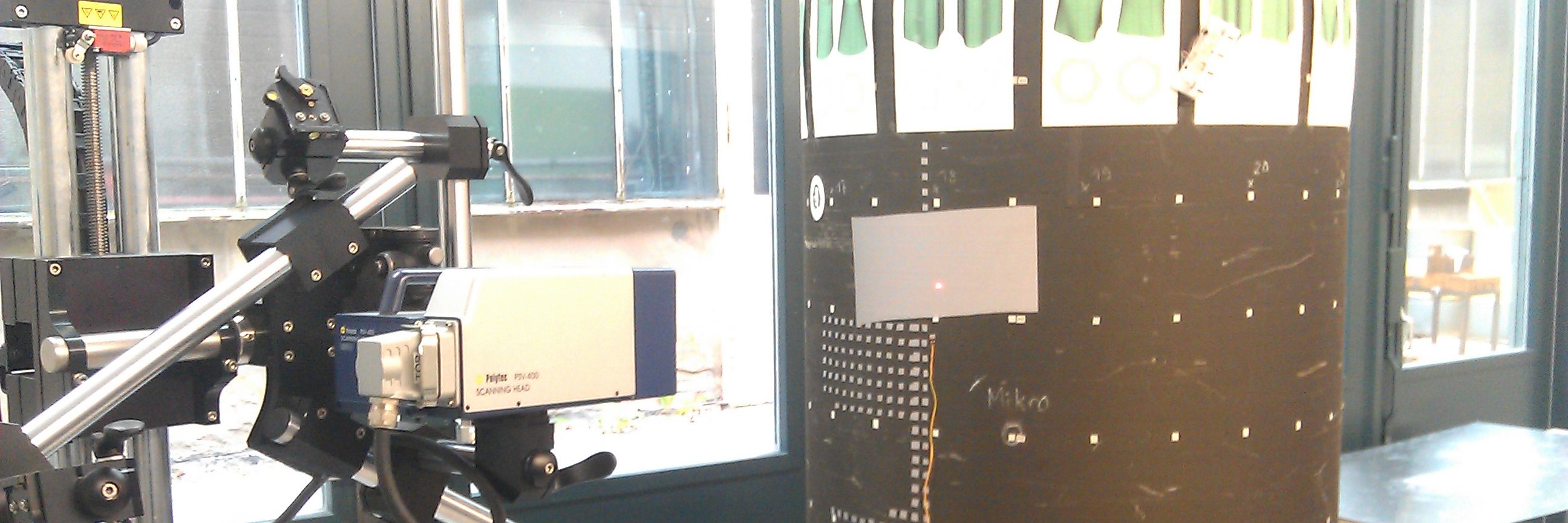

This project realized a custom-built numerically controlled (NC) rotary table, designed specifically for research into curved composite structures using a Laser Scanning Vibrometer (LSV). The system allows automated, high-precision measurement of wave propagation in cylindrical components like carbon fiber reinforced polymer (CFRP) structures, which are common in aerospace and other safety-critical applications.

The rotary table automates the rotation of test objects in small, predefined angles, making it possible to perform detailed measurements across the entire surface without the need to manually adjust the experimental setup. This functionality is critical for capturing accurate data in structural health monitoring (SHM), where detecting internal damage, such as delamination, can prevent catastrophic failure in operational environments.

In this project, I designed and implemented the mechanical system, including the shaft, bearings, and gear components. Electrical integration involved selecting and programming a stepper motor control system that interfaces seamlessly with the Polytec Laser Scanning Vibrometer software, automating the measurement cycle for efficient data collection. The system is fully capable of performing automated cycles of rotation and measurement, significantly enhancing the precision of wave propagation studies in curved structures.

Beyond its mechanical and electrical components, the rotary table was developed with extensibility in mind. The design allows for additional axes or sensors to be easily added, making it suitable for a wide range of SHM studies. For example, the addition of an XY table on top of the rotary table can extend its capabilities further. The low-cost design makes it a valuable asset for research laboratories that need high precision without the expense of commercial systems.

Although designed primarily for laboratory use, the rotary table provides significant flexibility in terms of future applications. Its modular construction and slip ring allow for extensive modifications, and it supports integration with various data acquisition systems, offering the potential for future upgrades or more complex experimental setups.

This project successfully met its objectives, delivering an affordable, functional rotary table for structural health monitoring research. The system’s ability to handle automated measurement cycles offers a scalable solution that bridges the gap between manual measurements and high-end commercial systems.